3 Signs Mold May Be Present in Your Facility’s Air Ducts

Leave a CommentWhile occasional moisture is acceptable in commercial air conveyance systems and ducts, excessive dampness can lead to problems with your air quality. Instead of evaporating, the moisture can develop into droplets of water. The combination of moisture and the availability of nutrients from skin cells, dust, and dirt is the perfect environment for mold to colonize and thrive.

Mold is hazardous no matter where it grows, but it presents a unique risk when occupying your air conveyance system. Airflow may carry the mold spores through the air ducts, spreading them throughout the facility. This blog will explain the three primary signs of microbial growth in your facility’s air ducts and the process for HVAC cleaning in commercial air ducts.

The Presence of a Musty Odor

Often the first sign that your air ducts contain microbial growth is a moldy, musty, or earthy odor. The scent may be subtle if the growth is contained to a small area or only be noticeable when the air conditioning, heating, or HVAC system starts. The variations in the strength of the scent can help pinpoint the location of the growth. When the ducts are not in use, the smell may become less noticeable as it settles.

Illness and Allergy Symptoms

The most serious risk of having mold in the air ducts is that it can cause irritation and health problems for personnel. The affected persons can experience skin, eye, and respiratory irritation when in contact with mold-contaminated air. Sneezing, coughing, headache, and fatigue are more severe symptoms of exposure and may increase over time. Those with existing allergies and sensitivities can exhibit extreme symptoms, such as nausea. It is critical to have the air ducts inspected and the mold eliminated if health problems arise for facility personnel.

Visible Mold in Air Ducts

The most obvious sign of microbial growth in an air conveyance system is a visible accumulation of mold in the duct, the air handling unit compartments, or at the vents. Mold typically grows within the air handling unit, but gets carried by the airflow and may settle around the vents. While mold is not visible in the air, dust and particulate matter can accumulate in patches of black, white, or green fungus on surfaces. To visually inspect for microbial growth in air ducts, open the air handling unit and blower compartment or vent and check inside with a flashlight.

The Air Duct Mold Removal Process

It is critical to remove mold quickly and safely when it is present in your facility’s air ducts. IMC’s commercial air duct cleaners remove mold in three steps:

- Inspect: We investigate areas of concern and work with the facility manager to identify possible sources of excess moisture and particulate accumulation. Other issues that may need to be resolved before starting an air duct cleaning project include possible insulation removal and replacement, insulation coatings, or other HVAC refurbishments.

- Containment Engineering Strategies: IMC will determine a strategy to isolate the workspace from other areas of a building. Barriers and pressure differentials are common strategies to prohibit the unwanted migration of airborne particles into other areas. Depending on the usage classification of a building and the type of contaminants within the HVAC system, several different containment engineering strategies may be employed. These containment engineering strategies are specifically designed with respect to protecting the indoor environment, contractors, and personnel from HVAC and duct cleaning procedures.

- Source Removal: IMC follows the standards set by the National Air Duct Cleaners Association (NADCA). We remove all visible contaminants and particulates from all components of the heating, ventilation, and air conditioning (HVAC) system. We use industry approved agitation tools for our cleaning operations including air whips, air sweeps, brushes, compressed air, and HEPA-filtered vacuums, each of which is designed for effective and efficient capture of accumulated particulate.

Air Duct Mold Cleaning From IMC

Mold and microbial growth in your facility’s air conveyance systems can be harmful to the health of personnel and is often a sign of particulate accumulation, insufficient filtration, or damaged HVAC components. Mold in your air ducts may be the culprit if you notice a musty smell, eye and respiratory irritation, or visible growth.

Airborne mold spores spread quickly in HVAC systems and can create a hazardous environment for occupants. Rely on IMC’s commercial air duct cleaning to eliminate the source of potential microbial growth in your facility. We have over 30 years of experience cleaning HVAC systems and air ducts according to National Air Duct Cleaners Association (NADCA) standards. Professionally cleaning your air ducts will improve your facility’s air quality, extend the life of your HVAC equipment, increase airflow, and reduce the risk of fire.

Contact us or request a quote to learn how our commercial air duct cleaning can improve your facility’s air quality.

The Ultimate Commercial HVAC Inspection Checklist

Leave a CommentEnergy costs take up a huge chunk of spending for commercial businesses each year. Lowering your energy spending can generate savings that can be used to expand your business and boost income. One way to do this is by starting with your HVAC systems, as they are one of the biggest energy consumers in the average commercial facility. Properly maintaining your HVAC systems reduces energy consumption and ensures reliable equipment performance.

Here, we provide the ultimate commercial HVAC inspection checklist. Following these best practices can lead to reduced energy consumption, prevent costly repairs or replacements, and ensure your system is running smoothly.

The Importance of Proactive HVAC Preventative Maintenance

Preventative maintenance plans involve inspecting your HVAC equipment and performing basic maintenance procedures (cleaning, lubricating, etc.) at scheduled intervals. HVAC preventative maintenance plans require consistent effort from a dedicated maintenance team. Although PM plans may incur routine maintenance costs, they significantly reduce costs associated with expensive repairs and replacements, making them worth it over time.

One of the most significant advantages of preventative maintenance is that it reduces the risk of emergency repairs. A PM plan also prolongs your equipment’s service life, reduces energy consumption, and ensures your system is operating as intended. By regularly inspecting and cleaning the various components of your commercial HVAC system, you can find potential problems and solve them before they cause catastrophic failure and unexpected downtime.

The Commercial HVAC Inspection Checklist

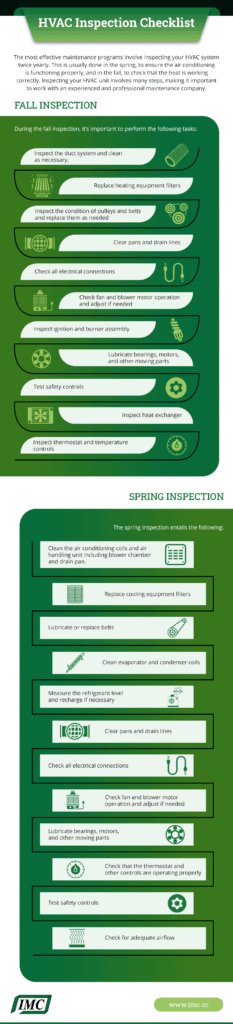

The most effective maintenance programs involve inspecting your HVAC system twice yearly. This is usually done in the spring, to ensure the air conditioning is functioning properly, and in the fall, to check that the heat is working correctly. Inspecting your HVAC unit involves many steps, making it important to work with an experienced and professional maintenance company.

Fall Inspection

During the fall inspection, it’s important to perform the following tasks:

- Inspect the duct system and clean as necessary.

- Replace heating equipment filters

- Inspect the condition of pulleys and belts and replace them as needed

- Clear pans and drain lines

- Check all electrical connections

- Check fan and blower motor operation and adjust if needed

- Inspect ignition and burner assembly

- Lubricate bearings, motors, and other moving parts

- Test safety controls

- Inspect heat exchanger

- Inspect thermostat and temperature controls

Spring inspection

The spring inspection entails the following:

- Clean the air conditioning coils and air handling unit including blower chamber and drain pan.

- Replace cooling equipment filters

- Lubricate or replace belts

- Clean evaporator and condenser coils

- Measure the refrigerant level and recharge if necessary

- Clear pans and drain lines

- Check all electrical connections

- Check fan and blower motor operation and adjust if needed

- Lubricate bearings, motors, and other moving parts

- Check that the thermostat and other controls are operating properly

- Test safety controls

- Check for adequate airflow

HVAC Preventative Maintenance from Interior Maintenance Company

Implementing a proper commercial HVAC preventative maintenance plan is crucial in reducing energy costs, prolonging the lifespan of equipment, and preventing costly emergency repairs. To ensure your HVAC system is inspected properly and thoroughly, it’s important to work with an experienced and reliable HVAC or Mechanical contractor with commercial and industrial experience.

As part of our capabilities, we offer commercial duct cleaning services designed to improve indoor air quality, decrease energy consumption, extend HVAC system service life, and enhance overall safety. We are NADCA certified, meaning we stay up to date on best practices for HVAC system inspection and cleaning. Whether you are in a small or large facility, we can handle almost any air duct cleaning project.

For more information about our air duct cleaning services, or to partner with IMC for your HVAC PM plan, contact us or request a quote today.