Fine particles of combustible material present a serious hazard, especially in manufacturing facilities. Not only does it cause extensive damage to sensitive equipment, but it is also a fire and explosion hazard. Why is it important to clean your facility regularly? One reason is to prevent dust accumulation. Ground-level dust usually doesn’t pose an issue to clean, but It’s more challenging to rid areas near the ceiling of dust and debris. Consequently, facility managers should consider high surface cleaning to protect expensive equipment. At Interior Maintenance Company, we have advanced training and specials tool to accomplish this process.

Dangers of Combustible Dust

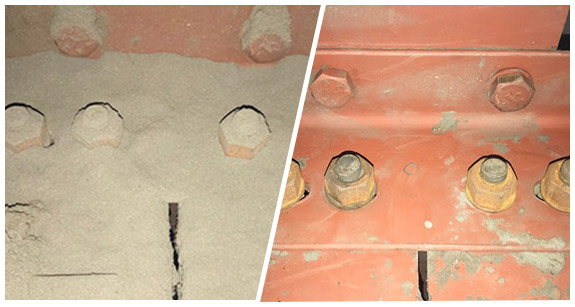

Combustible dust is a term that isn’t commonly known. It means any material or substance that can ignite when it comes into contact with a spark. This term also applies to liquids, gases, solids, and powders. One of the biggest dangers of combustible dust is that it can accumulate in large quantities without being seen or noticed. As a result of the accumulation on surfaces, it creates a fire or explosion hazard. Higher surfaces can quickly go unnoticed because they are not easily accessible.

One of the best ways to prevent this is to clean your facility regularly. Removing dust buildup from surfaces can significantly reduce the risk of a fire or explosion occurring due to combustible dust. Combustible dust becomes so dangerous in manufacturing facilities because it can ignite with energy sources, such as sparks, heat, or even static electricity.

Suppose you are concerned about the hazards of combustible dust in your facility. In that case, it is important to work with a professional cleaning company with the necessary experience and tools to remove this buildup effectively. At Interior Maintenance Company, our experienced technicians have the knowledge and tools to keep your facility safe. We also recommend regular cleanings to prevent dust buildup from accumulating over time.

Benefits of High Surface Cleaning

Many facilities have more than adequate cleaning processes for surfaces at the general ground level. However, it’s harder to see—and clean—the accumulation of dust on surfaces like the top of machinery, piping and conduit, ductwork, and exposed ceiling rafters. High surface cleaning operations target these areas, ensuring they are free from accumulated dust and debris.

In addition to reducing the risk of fire and explosion by minimizing combustible dust accumulation, high surface cleaning also provides a cleaner and brighter work environment.

Combustible Dust and High Surface Cleaning Services at IMC

If not prevented or contained, combustible dust can be highly detrimental to various buildings. A regular combustible dust cleaning program doesn’t just invest in the appearance of your facilities but also prevents dangerous dust accumulation. At IMC, our experts will care for your combustible dust and high surface cleaning needs.

If you require combustible dust or high surface cleaning for your manufacturing or production facility, then IMC is the company for you. We have plenty of experience with these cleaning requests and always aim to provide the best quality care possible. Please note that there is a minimum requirement of 10,000 square feet before we can begin any work.

Due to the delicate nature of the work involved, IMC only uses the safest and most effective equipment available to remove combustible dust. We utilize an explosive-proof vacuum with a HEPA filter to safely remove harmful debris from high surfaces. Also, we have the equipment necessary to reach high surfaces, such as ladders, scaffolding, and lifts, while always staying in compliance with OSHA safety standards. Our services can benefit several industries, including manufacturing facilities for plastics, metal, food, chemicals, and more. With our experience, we have evolved into a premier provider of high surface cleaning services. If you require combustible dust cleaning services for your facility, contact us or request a quote today.